- Home

- Education & Insights

- Search

- How Desiccants Safeguard Medical Devices

How Desiccants Safeguard Medical Devices

Table of content

The integrity of medical devices is paramount, and desiccants ensure these devices remain functional and safe to use. Whether it's preserving the efficacy of drugs or maintaining the mechanical functions of complex instruments, desiccants are indispensable.

Why Moisture and Oxygen Control Matter

Moisture in medical devices is more than a nuisance—it’s a silent threat. It can cause corrosion, promote microbial growth, degrade sensitive materials, and even render the device ineffective or unsafe for use. Similarly, oxygen can be highly reactive, leading to damage in delicate components. Advanced medical devices demand rigorous control of both moisture and oxygen to maintain their integrity, reliability, and shelf life. Desiccants and oxygen absorbers are the first line of defense, protecting against environmental degradation and ensuring device performance.

Preventing Corrosion

Many medical devices contain metal components that are susceptible to corrosion when exposed to moisture and oxygen. This corrosion can weaken the structural and functional integrity of devices, making them unsafe for use. Desiccants absorb excess moisture, while oxygen absorbers remove residual oxygen—together preventing the onset of corrosion and extending the life of the device.

Inhibiting Microbial Growth

Moist environments are breeding grounds for bacteria and fungi. Oxygen also supports the survival of many aerobic microbes. In medical devices, the presence of such microbes can lead to infections and other health complications. By maintaining a dry, low-oxygen environment, desiccants and oxygen absorbers work together to inhibit microbial growth and ensure that medical devices remain sterile and safe for use.

Maintaining Mechanical Functionality

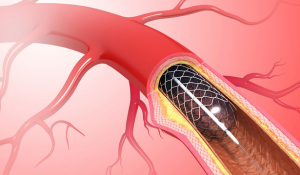

Medical devices often contain numerous mechanical and electronic components. Moisture can interfere with the proper functioning of these components, leading to malfunctions or total device failure. Desiccants are used within the device casing to maintain a dry environment, ensuring the device operates smoothly.

Protecting Electronic Components

Electronic medical devices, such as insulin pumps, are particularly vulnerable to moisture. Even a small amount of humidity can cause short circuits or damage sensitive electronic parts. Desiccants absorb residual moisture within the device, protecting the electronics and ensuring reliable performance.

Types of Desiccants Used in Medical Devices

There are various types of desiccants, each with unique properties and applications. The most used desiccants in medical devices include silica gel and molecular sieves but newer technologies like injection molded desiccants have emerged in recent years.

1. Silica Gel

Silica gel is one of the most widely used desiccants due to its high absorption capacity and stability. It is often used in packaging to protect drugs and medical products from moisture and oxygen, helping to preserve their efficacy and shelf life.

2. Molecular Sieves

Molecular sieves are synthetic zeolites with a high affinity for water molecules. They are particularly effective in environments with low humidity and are used in applications requiring precise moisture control. Certain types of molecular sieves can also adsorb oxygen, making them useful in packaging that requires dual moisture and oxygen protection.

3. Injection Molded Desiccants

Specially designed plastic components that incorporate desiccant materials directly into the plastic during the injection molding process. These components can be engineered to absorb both moisture and oxygen, providing integrated protection for sensitive medical devices and pharmaceuticals.

Final Thoughts

Often hidden from view, desiccants play a vital role protecting medical devices. They protect the structural, mechanical, and electronic integrity of medical devices—contributing directly to patient safety and product reliability. As medical technologies evolve, the need for precise environmental control will only grow, and desiccants will continue to be a small but mighty part of the solution.