- Home

- Products

- Film Coatings

- Pharmaceuticals

- Opadry® Coating Systems

- Opadry®TF, TiO2 Free Film Coatings

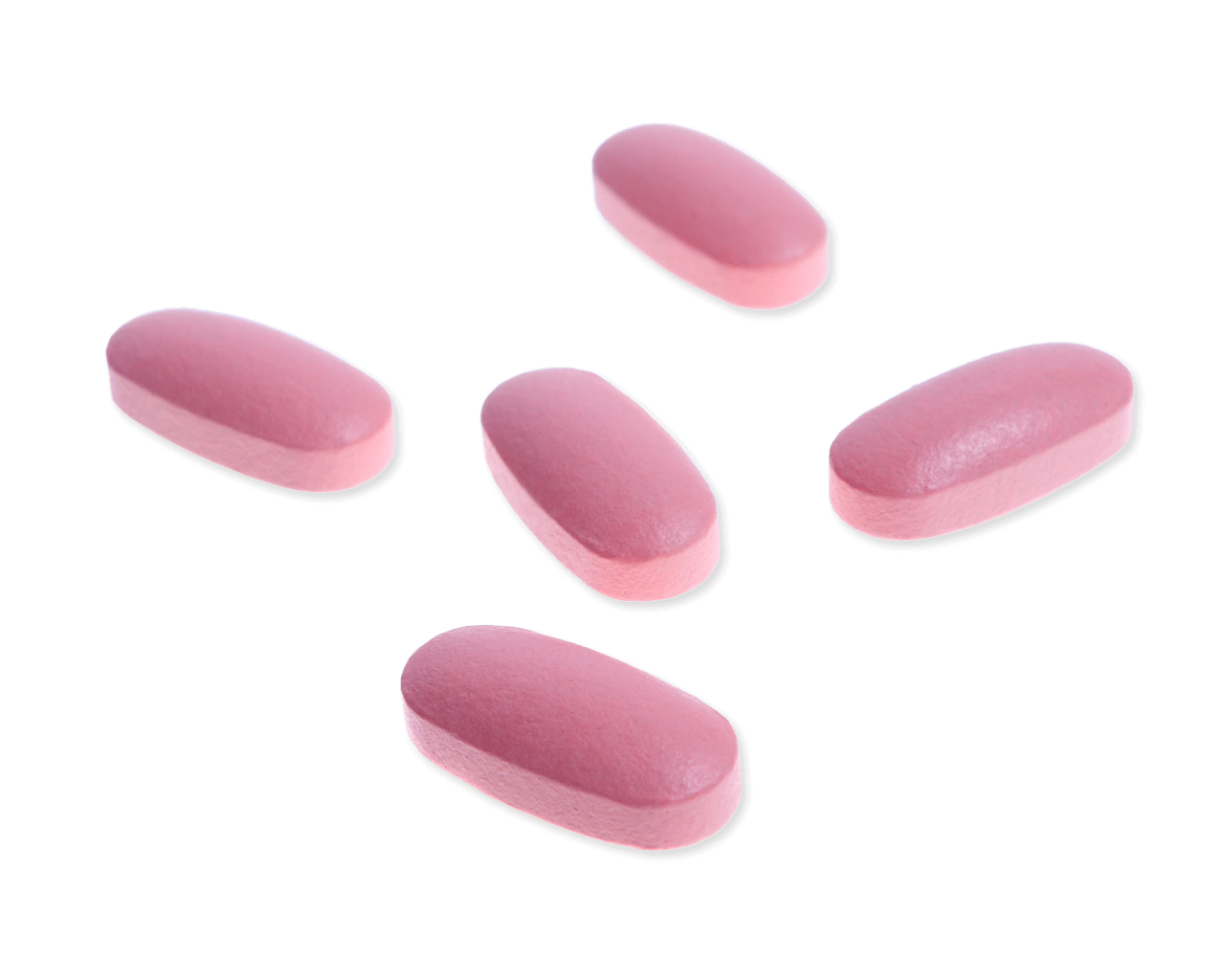

Opadry® TF

TiO2-Free Film Coatings

To address consumer concerns around the use of titanium dioxide (TiO2), Colorcon offers a wide range of coating solutions free from titanium dioxide, providing the same superior finish and efficient performance manufacturers expect from us. Our Opadry TF portfolio is available with different polymers and opacifiers.

Already Using Opadry® TF?

Visit My Colorcon to access Tools & Calculators for Process Recommendations; Answer Center for Product Knowledge; and HyperStart C2C® for Formulation Advice.

Explore Other Products

Education & Insights

As industry leaders for more than 60 years, we're committed to continuous innovation and to providing customers like you with the knowledge, education and resources needed to succeed.

Request a Sample

Ready to experience the Colorcon difference? Request a sample today and see firsthand how our innovative solutions can elevate your products.

.png)

.png)

.png)