Fluid Bed Best Practices for Multiparticulate Formulations – Part 3

Achieving Functional Performance through Film Coating Properties and Application Process

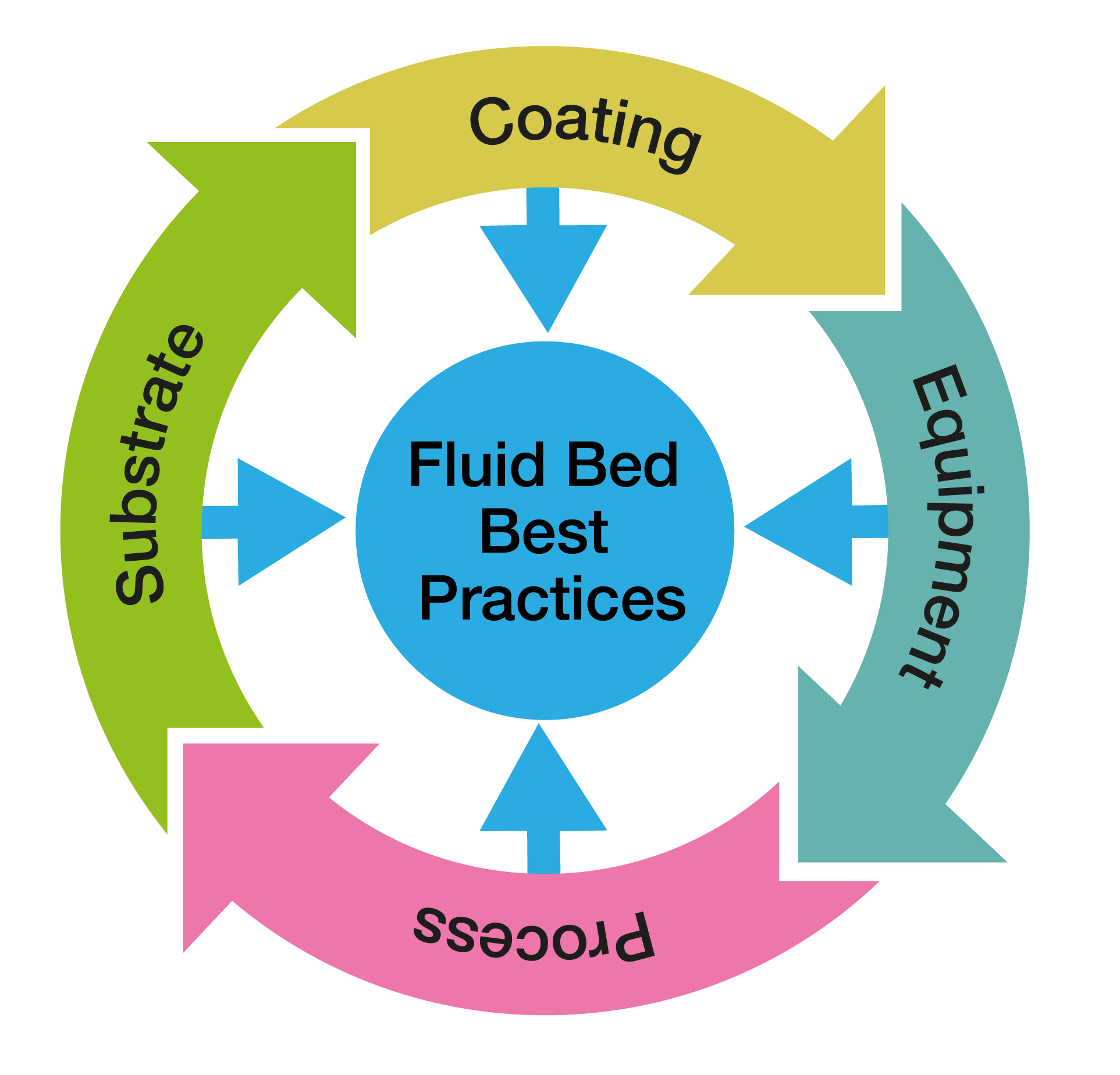

Multiparticulate dosage forms are complex, and the application of coatings to extend drug release can present challenges. Substrate properties, coating formulation, equipment and process conditions are all considerations that affect final drug release. Colorcon has developed best practice guidelines to accelerate product development and support consistent manufacture throughout the lifecycle of your commercial multiparticulate dosage product.

Multiparticulate dosage forms are complex, and the application of coatings to extend drug release can present challenges. Substrate properties, coating formulation, equipment and process conditions are all considerations that affect final drug release. Colorcon has developed best practice guidelines to accelerate product development and support consistent manufacture throughout the lifecycle of your commercial multiparticulate dosage product.

This third installment covers the importance of film coating properties and the application process when coating multiparticulates for extended release performance.

Film Coating Properties that Meet Performance Targets and Manufacturing Efficiency

Film formation using aqueous latex coatings (e.g. Surelease®, Ethylcellulose Dispersion Type B NF and Aquacoat®) differs significantly from organic solutions (e.g. Opadry® EC, Ethylcellulose Organic Coating System) of the same polymers. With aqueous latex film coatings, the polymer is presented as a dispersion of discrete polymer particles and film formation occurs as water evaporates and the polymer particles closely pack at the substrate surface. In the presence of energy (heat), the polymer particles coalesce to form a film. Whilst, with organic coating systems, film formation occurs freely at the substrate and coating interface as the solvent evaporates and polymer chains form the resulting film.

Fully formulated coating systems, whether applied aqueously or via organic solvents, are typically a combination of film-forming polymer, plasticizer, stabilizers (aqueous systems) and processing aids. They are optimally designed to be applied at a high solids content, within a broad range of process conditions, promoting efficient and complete film formation. To withstand the rigors of fluid bed processing and subsequent unit operations, these systems are formulated to provide optimal film properties, such as tensile strength and elasticity.

Coating Application Process Parameters

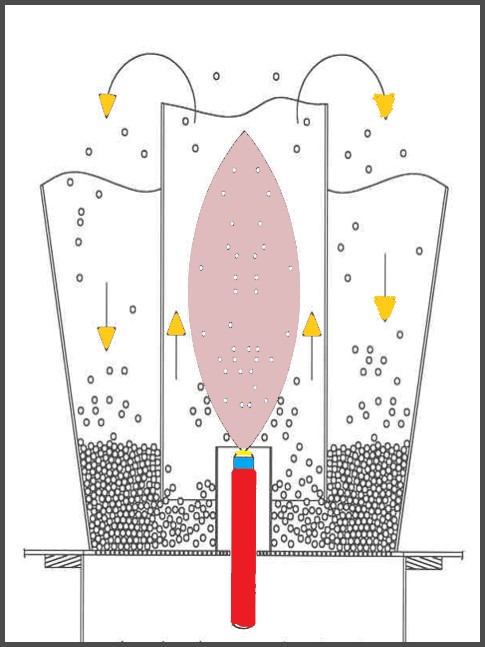

Successful multiparticulate coating using a fluid bed application involves a complex balance of process parameters to ensure complete film formation. The efficiency of the process involves droplet formation, contact with the substrate, droplet spreading, and solvent evaporation. At the center of this process is the spray nozzle and the ability to uniformly deliver the coating to the substrate surface is considered critical (Figure 1).

Coating of small particles (less than 100 microns) can be especially challenging and coating conditions must be optimal to maximize coating uniformity and process efficiency while avoiding unwanted agglomeration. Various analytical techniques, including phase-doppler analysis, have been successfully used to characterize droplet size and velocity profiles generated from both laboratory and production scale fluid-bed nozzles (reference: Colorcon AAPS Poster, 2014). Information from these studies often provides invaluable nozzle performance and spray conditions for coating of particles of various sizes in a fluid-bed coater, at both laboratory and production scale.

Curing of aqueous latex films is a common concern when considering storage stability and potential changes in performance with time. When a decrease in release rate is observed on stability, then the need for a curing step, or post-coating thermal treatment, is called into question. This change can often be traced back to the application parameters used at the time of the initial coating. If the initial coating parameters are not optimized to ensure complete film formation (coalescence), then changes in the release may be observed over time. Ensure complete film formation and eliminate the need for a curing step by coating above the minimum film-forming temperature and approaching the glass transition temperature of the polymer for aqueous dispersions.

Considerations for Multiparticulate Processing

- To achieve long-term storage stability, apply coatings according to Colorcon’s recommended parameters.

- Evaluate the need for a curing step and balance process parameters to ensure complete film formation.

- Optimize the process to maximize coating uniformity and process efficiency, while avoiding unwanted agglomeration.

Formulation and Process Knowledge to Speed Development and Build Quality

To assist with the development of multiparticulate formulations, Colorcon offers consulting through My Dosage Design™, a theoretical modeling tool that helps determine optimal starting particle size, surface area to film thickness ratio, the volume of the final dosage and optimal capsule size selection.

Let us help you select your coating formulation and starting substrate on your next formulation. Connect with Colorcon to embark on a new multiparticulate project.